Trenchless Technology

FACTS ABOUT TRENCHLESS TECHNOLOGY (TT)

- With respect to wastewater TT can truly be a no-dig activity.

- Replacing the aging water and wastewater networks requires no major excavations with the discovery of TT.

- Minimum disruption to surface life.

- TT can be used for reconstruction of the networks within dense urban settings.

- According to research most of the total cost of utility projects (open-cut) is attributed to backfilling, compaction and the replacement of landscaping and pavement.

WHY OPT FOR TT?

1. STORM WATER CONTROL

- Conventional excavation for sewers often intercepts with storm water channels which has to be maintained

2. ROAD REINSTATEMENT

- Surface restoration on larger scale is needed to restore the business life

3. DAMAGE TO OTHER SERVICES

Generally sewers are the deepest utility.

- Thus during excavation often adjacent utilities are damaged

DYNAMICS OF TRENCHLESS TECHNOLOGY

- Substantial savings as no road repair is required

- Maintenance delays are reduced

- Much less intrusive, hence contributes to better relations with public and residents

SUSTAINABILITY OF TRENCHLESS TECHNOLOGY

- Trenchless construction pays off due to improved reliability

- Longer lifespans of the installation

- Minimal vibrations

- Easy to forecast expenses and final dates

- Careful handling of nature and structures

- Ground water table needs not to be dropped

- Low dependency of construction cost to depth

- Minimization of CO2 emissions

KEY ADVANTAGES OF TRENCHLESS TECHNOLOY

- Reduction in required surface restoration

- Reduction of damage to adjoining utilities

- Decrease in disturbance to local residents and businesses

- Increase of flexibility in choosing depth of new installation which may allow more favorable

- Less relationship exist b/w cost & depth of new installation

- Reduction in number of utility relocations

- Reduction in the amount of soil disposal

- Improvement in safety for the people and job site workers

- Reduction of the disturbance to traffic flow

- Ability to install pipes irrespective of weather

- Reduction in access requirements (main advantage for urban areas)

- Possibility of speed up work

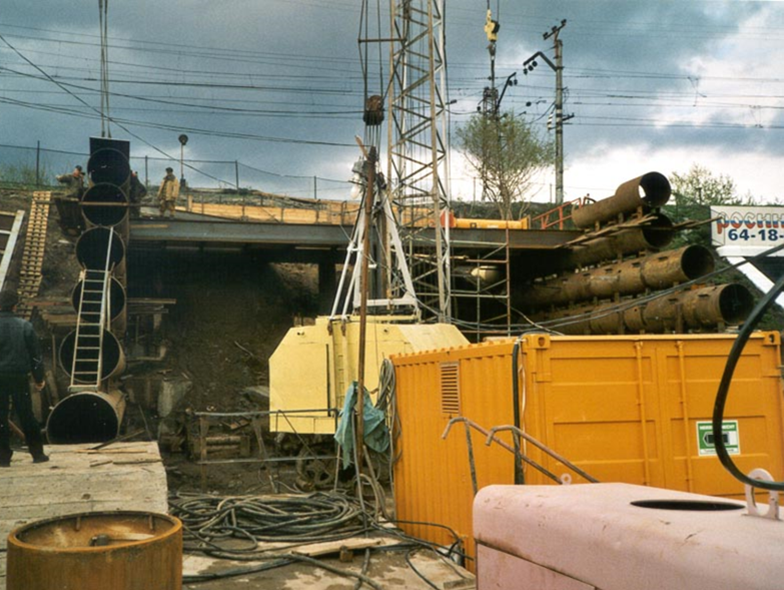

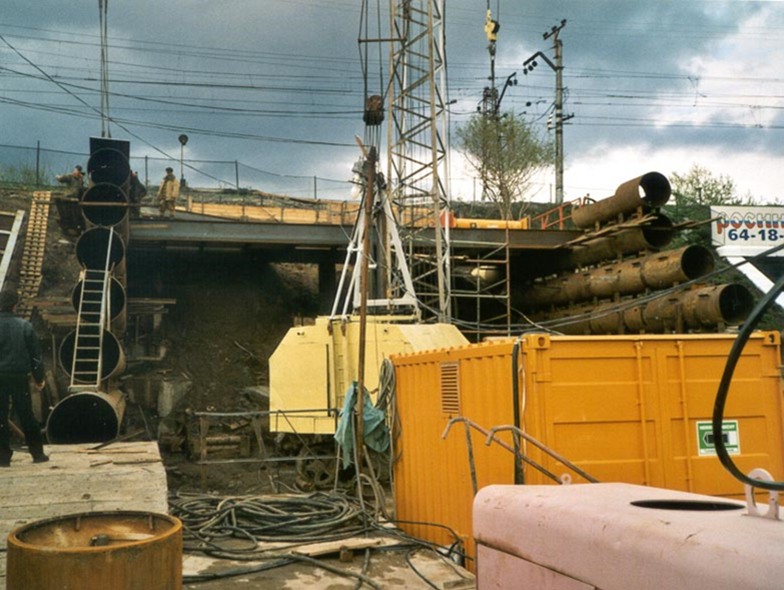

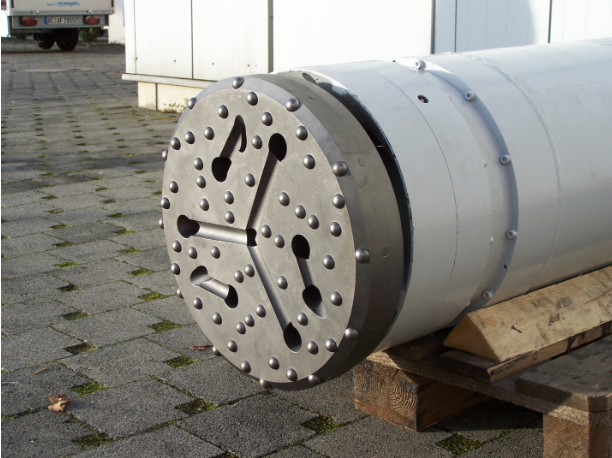

PIPE JACKING

It is defined as a system of ;

” Directly installing pipes behind a shield machine by hydraulic jacking from a drive shaft such that the pipes form a continuous string in the ground till the receiving pit “

METHODOLOGY

Launching and Receiving Shafts are constructed at both ends of the proposed tunnel.

A thrust wall is constructed to provide jacking reaction.

Hydraulic jacks push the pipes on the drive. The TBM is located in front of them.

Once the thrust cylinders are completely extended, they are retracted to let the necessary

space to install the next pipe.

Generally concrete pipes are used equipped on one end with steel collar (female side) and the

other side shaped to enter in this collar on the other side (male).

Rubber joins are assuming the water tightness.

The Pipes are directly pushed through soil while boring machine excavates the ground.

MICRO TUNNELLING

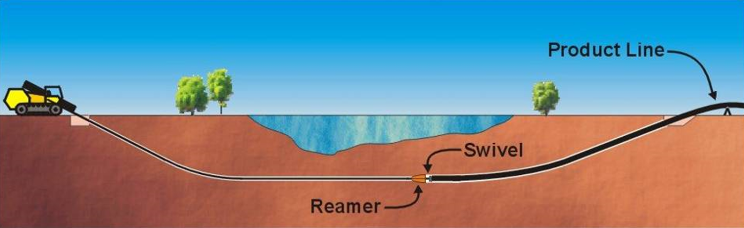

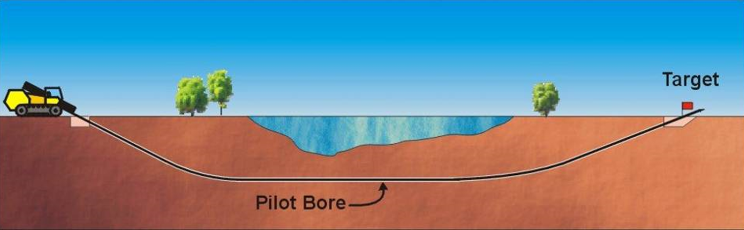

1. HORIZONTAL DIRECTIONAL DRILLING

1.1 FEATURES

- Larger Lengths

- Diameters of 0.2m – 02m

- Wide range of utility conduits

- Pipelines

- Gravity sewers

- Force mains

- Horizontal remediation wells

- Geotechnical investigations

2. DIRECT PIPE

DIRECT PIPE IS AN UNMATCHABLE AND UNIQUE COMBINATION OF TWO TECHNOLOGIES

2.1 FEATURES

- Combination of advantages of HDD and micro tunneling technology which excavates the soil from launching pit

- Diameter ranges are 0.8m to 1.5m

- Pipeline can be installed in one single step with borehole being excavated at the same time

- More than 1500m can be excavated using Direct pipe technology

- Highly economic

- Very high installation speeds

- Precise steering possible

- No impact on surface

- Pre-Fabricated pipes can be installed all in one go

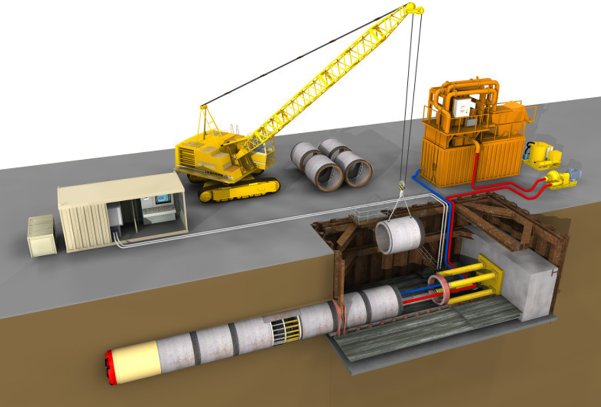

3. AUGER BORING

Successful installation of sewers and pipelines beneath the infrastructures can be achieved by

Auger Boring Machines.Main range of application is Pipe Jacking with comparatively small diameters and lengths up to

120m.

3.1 FEATURES

- Minimum impact on environment with low costs

- Excellent performance in dry soft ground

- Highly suitable to install house connections and pipelines quickly and safely

- Excavation diameters ranges from 0.1 to 1.4m

- Depending on the availability of space, compact machines and long frame machines are used

- For smaller drives unguided machines are used. For longer, guided drill is used for higher precision